The Chef First Encounters Sous Vide

I started working in hotel/restaurant kitchens just prior to 1970, so the use of Sous Vide was actually evolving in parallel to the procession of my own culinary odyssey. We avoided each other, in a manner of speaking, except for fleeting encounters in the 80’s and 90’s; things like baby carrots in bags and a few culinary practical jokes; you can use your imagination. I was totally dug into kitchen life, but SV didn’t gain much traction in the restaurant industry until these last 20 years. We didn’t have the specialized equipment, and the process seemed so different from traditional methods.

It turned the idea of food safety upside down. There was NO WAY food could be safe to eat at tap water temperatures. YER GONNA GET SICK! I hope you get WORMS! E. Coli! People STILL say that. Sous Vide is like the global warming of the food industry—the science is there, but, it’s different, and counter intuitive, so it must be DANGEROUS! It’s amazing that humans ever even managed to use the wheel, which must have been extremely controversial when it was introduced. “Dragging, GOOD. Rolling, BAD!”

Sous Vide Begins To Catch On

Meanwhile, large food processors didn’t hesitate to take advantage of the cost saving and pasteurizing properties of SV, and they implemented SV in their factories with little delay or fanfare. With all the science backing them up, there would be little resistance from well informed USDA inspectors. Whenever you visit the deli counter of your local supermarket, and even the freezer section, you will encounter a laundry list of products that have been processed SV—everything from that turkey, ham, and roast beef that they slice for sandwiches, all the name brands, and the full sized deli meats like Mortadella, etc. You can be pretty sure that if it’s wrapped in that tight, sturdy vacuum plastic, that it was “cooked” (pasteurized) right there in that bag.

Thomas Keller ‘s Landmark Under Pressure Book

2005 – Norm Dips His Toe In

And, so it was, that in 2005, SV and I finally got acquainted. I had just taken the Chef position at a well-established steak house and “watering hole” in a suburb of the San Fancisco Bay Area, and there was another popular restaurant nearby. We weren’t really competitors, they were much smaller, but highly regarded locally, and we shared customers. We also shared a sales representative, with whom I had established a very close working relationship. I was her biggest account, and the other restaurant was among her smallest. Naturally, in the process of our conversations, we would discuss local businesses, gossip just a little, and try to keep current with who was doing what, and HOW MUCH, if you get my drift.

I must have asked my rep how such a small place could manage to avoid the inevitable spoilage inherent in restaurants with less than 50 seats. I had worked in places that small before, and it was usually a big obstacle to staying in business. Among other strategies, she mentioned that the chef/owner of the other restaurant was implementing SV in a LOT of his products and menu items. I was intrigued, so I started to investigate. As I read everything I could get my hands on by innovators like Thomas Keller, Nathan Myhrvold’ , and, later, Baldwin, I reveled at the huge potential of the technology. This was before Keller’s Under Pressure and Myhrvold’s Modernist Cuisine were published, so sites like eGullet were a primary source of information.

The consensus seemed to suggest that tougher, presumably cheaper, cuts of beef were good candidates for processing. Famous chefs were already marketing their versions of things like “72 hour short ribs,” and so on. The restaurant where I worked ran short ribs as a sort of monthly special, and they were very popular, while being rather horrible and plain. Plus, that restaurant down the street was running them, providing a little sport. I had been experimenting with different kinds of sous vide technique and shared some samples with the owner of the restaurant, who was favorably disposed.

We started introducing sous vide items into the menu, along with the HACCP plan, and began to share the method and reasoning with all the cooks. Some took to it immediately while other fought it tooth and nail. But the Rubicon had been crossed. I was committed to sous vide as a viable way of providing food that was flavorful, different and high quality.

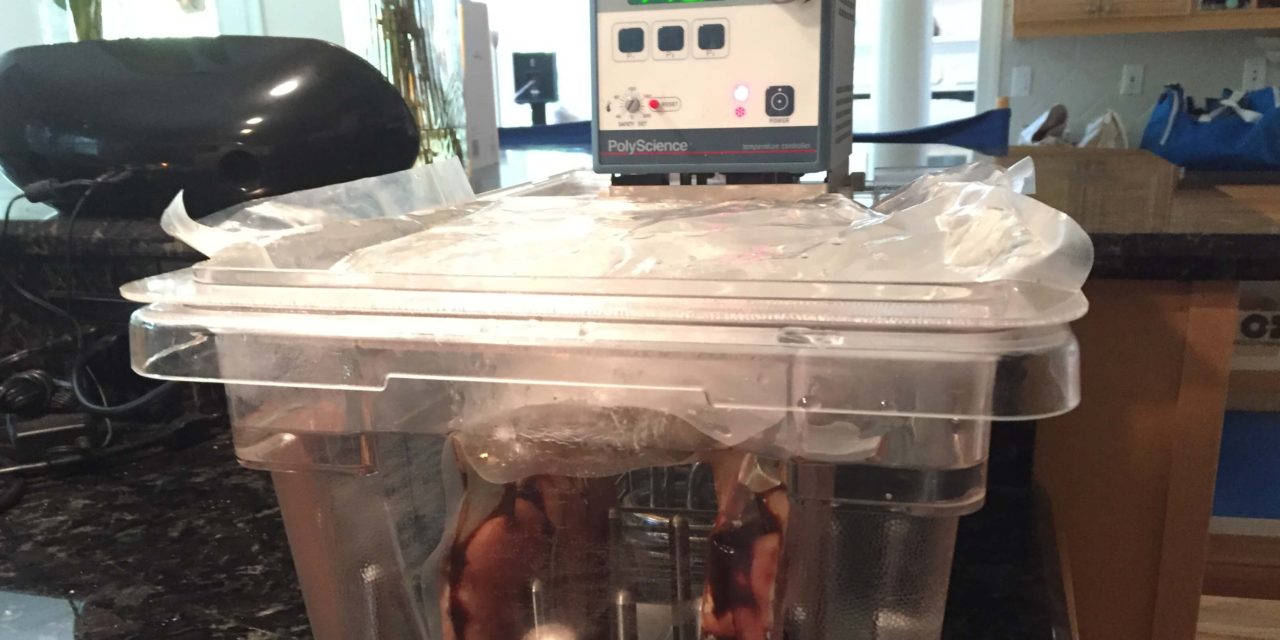

Gearing Up For Sous Vide

SV equipment was still pretty expensive and limited in availability, so we acquired an immersion tank from a laboratory supply company. Our unit was accurate to a degree Fahrenheit, shaped like a full, hotel sized insert (a standard for steam tables and most restaurant storage). It cost us $400, which seemed like kind of a lot, until the price went up to $700 in a couple of months. As it turned out, SV was finally penetrating the restaurant market, and people were flocking to the laboratory supply places to sneak in under the SV novelty pricing radar. Immersion circulators, a portable device about the size of a hand blender, have since supplanted the popularity of the self-enclosed tanks. The user provides his/her own tank, bucket, pot, plastic cooler, or whatever he/she chooses; there’s a lot of flexibility because of the low temperatures used. At home, I even use the sink itself, when I have a project of four hours or less. Clearly I was hooked on Sous Vide.

Then Twenty Five Years Flew By

I worked at a lot of different restaurants up and down the west coast. Vegas, San Francisco, etc. When you’re busy the time just seems to slip away. Fast forward to 2008. As for me, I was the not so proud owner of a toxic mortgage. As I struggled to keep my head above water financially, my health started to fail. Like a lot of chefs, I was overweight. I had broken a bone in my shoulder that required surgery, and, as a result, the Dr.’s discovered that I had high blood pressure, congestive heart failure, and, worst of all, COPD. 25 years of tobacco abuse had left me with about 12% of the lung volume that would otherwise be predicted for a man of my age.

I’m not complaining. I’m just laying out the facts as they occurred. My wife and I had both left the employ of the last restaurant we worked at. The money wasn’t coming in, so we handed over the keys to our house, consolidated our finances through a chapter 11 proceeding and moved to Oregon to start things over on a much smaller, much more compact basis. It was humbling, but it also took some of the pressure away as well.

Once we got situated, a very good friend gave me a homemade PID / Sous Vide setup. With the aid of laptop computer I found my way to Facebook and setup a group with the eloquent name “Sous Vide, Meat Curing, BBQ, Slide and Blues Guitar“. My thought was to pay it forward and share some of what I learned about Sous Vide with those folks who were interested. It took nearly a year to get to 100 members. And then things started to grow. As of August 2016, we have 6400+ members and continue to grow every week. We post, share pictures and methods, agree, disagree, agree to disagree, argue, discuss and even bounce some people that won’t read the rules. But, for the most part it’s a great cross-section of Sous Vide devotees.

And Now We Have Sous Vide Resources

That brings us to this site, Sous Vide Resources. I set it up with a friend because websites are a better medium to share full recipes and instructions. They’re easier to search, easier to read and easier to maintain. We’ll keep the Facebook Group going as well. It’s a great place to have discussions. I hope you find both locations valuable.

Norm King

[paypal_donation_button]