A high steaks proposition

Level of difficulty: 2.75

Portion size–depends on your appetite!

Meet the meat

This is not one of those impossible to execute recipes that begins with the phrase “pick a cool and breezy day.” Each of the steps is extraordinarily simple–most of your time will be spent letting the beef’s natural enzymes and oxygen perform their designated tasks. But if you start with a whole bone-in beef rib eye, you are about six weeks and one day away from full completion. WHAT? The 45 day drying process is designed to achieve a level of tenderness and flavor concentration unattainable by any other method.

Restaurants customarily hyperbolize their menu descriptions–this is not news. Diners are used to seeing the term “aged” applied to steaks. Of course, there is no standardized or legal definition of what this actually means. All market beef is “aged” to the extent that after slaughter and during shipping, it rests in the sealed plastic packaging for 30 days or so. This practice originated in the 1960’s and is referred to as “wet aging.” Vacuum packed in the oxygen free environment, naturally occurring enzymes serve to tenderize the meat to an extent.

High and dry

On the other hand, dry aging has been around a long time. While it utilizes the same enzymatic action as wet aging, the additional exposure to cooled oxygen over an extended period of time concentrates flavor by removing moisture. This process can be extended up to 60 days and even longer in some cases. Until recently, dry aging proteins at home was challenging. While the meat must be exposed to oxygen, it must also be protected from exposure to the elements from its surroundings. You can buy an extra refrigerator and dedicate it to the process if you so prefer. Or, you can use UMAi products. This rib eye was wet aged before we purchased it, and then dry aged using the UMAi Dry® method.

UMAi Dry® is an established company that utilizes unique scientifically-proven, chef-tested technology that allows anyone to create dry aged meats at home. The semi-porous membrane’s material forms a bond with the proteins on the surface of the meat. This enables moisture release/oxygen exchange while blocking odors/contamination and preventing spoilage. UMAi products can also be used to make capicola, prosciutto, etc., as well as assorted dried sausages. For more information on the dry curing process, visit our own testimony HERE.

Pick a day–any day

Remove the roast from the packaging. Moisten the surface and stage the roast into the appropriate UMAi bag. Vacuum seal as per the directions. At first, the package will appear air tight like any sous vide product.

Stand by to wait

Six weeks can seem like forever

Weigh the meat after 45 days. It should have lost at least 25% of its original weight–the bones themselves will not lose weight. If not, you may proceed or return to the refrigerator until it does!

By the numbers

Dry aged steaks and roasts in restaurants can be very expensive. Prices for raw bone-in rib eyes vary widely and depend on whether you choose prime, choice, or select grades. Grading is very subjective and is driven by conformation (shape of the animal), size, maturity, marble and other factors. All of these three grades are equally wholesome for consumption. We used select grade, which we purchased wholesale for about $9/lb. This means that after losing 25% of its weight, the price of the roast worked out to about $12/lb.–about $.75/oz. If you choose choice or prime grades, expect to spend considerably more than that–I saw prime, bone-in “prime” rib recently at $22/lb.

Each heel weighs about 3.75 oz/100g, as we mentioned above. The larger the roast at the onset, the less waste ensues. Taking the additional18 oz/510 g of trim into account, this puts the cost of a fully trimmed steak at almost $30. That’s the steak alone–not including accouterments like a loaded baked potato, vegetables or sauce. Even if the steak is split between two people, the product cost becomes about $15/person. Extrapolating for the purpose of service in a restaurant, the cost of an item must be (at least) tripled to account for the costs inherent in running a food service establishment. Labor, payroll taxes and rent are not cheap. The cost of upkeep, dishes, laundry, water, electric refrigeration and gas stoves can be shocking to “civilians.” In order to keep the restaurant open, the menu price for an item like this must be at least $50/person. During the current pandemic, it’s easy to understand why restaurant owners seem panic stricken.

If you go to a restaurant and see “dry aged” steaks on the menu for less than that, you have reason to be suspicious. This does not mean that high prices guarantee they are really serving dry aged beef. This means that if they are NOT charging that much for dry aged beef, they will not be open for long so dig in. The days of high profit bar sales subsidizing an underperforming dining room are over. Some bartenders “reason” that the owner can afford to comp drinks because the restaurant’s margin will cover the cost. This was never true.

Now that we’ve sobered up

Preheat you sous vide bath to 129 F/54 C.

Taking stock of the many blessings

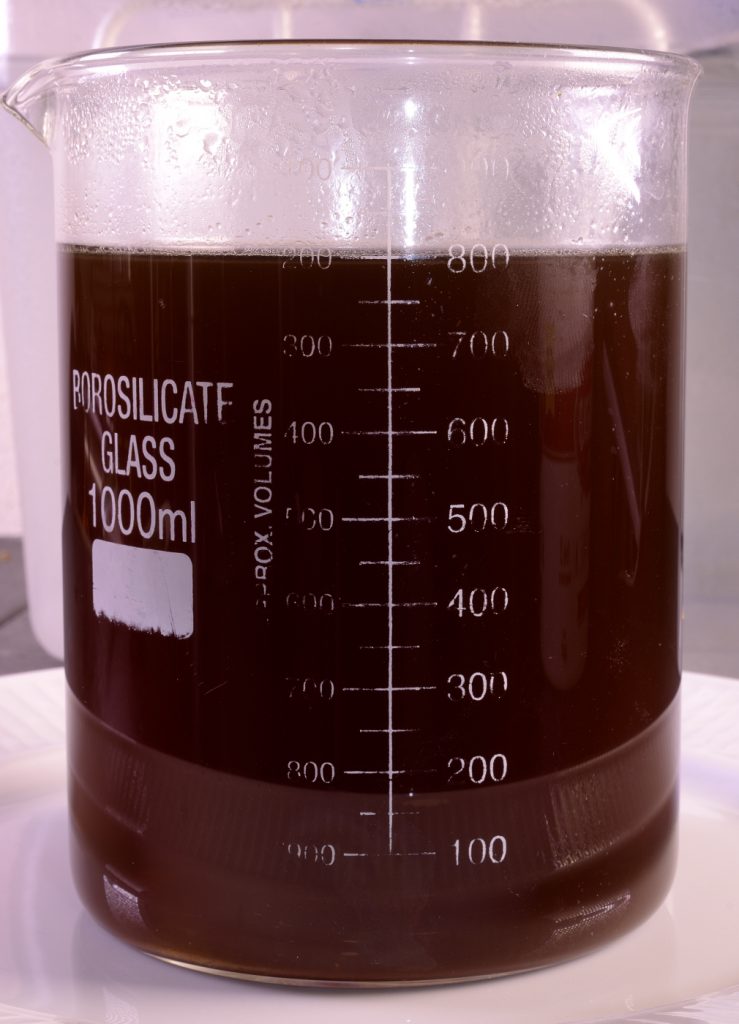

Fry the trim in a thick bottomed skillet with small amount of oil until lightly browned. Add one carrot, 2 stalks of celery and a coarse cut onion and continue to fry until the vegetables brown. Add 2 quarts/2 l of water, bring to a boil and simmer for a minimum of two hours.

Strain and clarify as explained here. This is an unsalted, full bodied, rich consommé that can be seasoned and utilized as a simple jus or in any recipe that calls for stock.

The upper crust

Put the peddle to the meddle.

Preheat your searing surface to at least 350 F/176 C. Cast iron, stainless steel, carbon steel, aluminum skillets or broiler grates are all suitable, the thicker the better. I heat service plates in an oven set at 170 F/77 C. There oughta be a law against putting a hot steak on a cold plate.

I wish I could find a steakhouse that served this.

Norm

Be sure to visit us in real time on Facebook at SVR–Sous Vide Resources; Low Temperature Pasteurization, Sous-B-Q™, | Facebook